Why vaccines should not be stored in ordinary household refrigerators ?

Special Cold Chain Products must be used

Vaccine is very sensitive to heat. . It will rapidly lose its potency at temperatures higher than +8°C. Once potency has been lost through exposure to heat or cold it cannot be regained by returning the vaccine to the correct storage temperature. If potency is lost through heat exposure, vaccines do not change their appearance so it is not possible to see whether a vaccine in a vial has lost its potency without a complete laboratory test. As long as Polio vaccine are kept between 0 to 8C it may be thawed and frozen again without danger to the vaccine potency and there for at any stage of the cold chain, vaccine must be transported between 0 to +8C.

Low thermic stability

A standard vaccine vial contains only 10 grammes of liquid and has very low thermic stability. The temperature in the vial will increase almost immediately if it is exposed to a warmer surrounding.Food stuffs on the contrary are in bigger pieces. They have higher thermic stability. The temperature in the food will increase much slower. In view of these facts Ordinary household refrigerators and Themos Flask have inadequate cooling systems for vaccine.

Top Lid

When a normal refrigerator with front door is opened the cold air in the cabinet will fall out. When the door is closed new warm air has to be cooled. Normal food with good thermic stability will not be much affected. But the. increase of temperature in the cabinet may easily destroy the vaccine. A box with a top lid retains most of the cold air when it is opened. Therefore all Blow Kings Cold Chain equipment have top lid.A box with a top lid is preferable also because vaccine can be stored in the whole interior space.

Conclusion:

In view of the above facts Vaccines must always be kept, stored, and distributed at refrigeration temperature to preserve the effectiveness of the vaccines.

Vaccine is very sensitive to heat. . It will rapidly lose its potency at temperatures higher than +8°C. Once potency has been lost through exposure to heat or cold it cannot be regained by returning the vaccine to the correct storage temperature. If potency is lost through heat exposure, vaccines do not change their appearance so it is not possible to see whether a vaccine in a vial has lost its potency without a complete laboratory test. As long as Polio vaccine are kept between 0 to 8C it may be thawed and frozen again without danger to the vaccine potency and there for at any stage of the cold chain, vaccine must be transported between 0 to +8C.

Low thermic stability

A standard vaccine vial contains only 10 grammes of liquid and has very low thermic stability. The temperature in the vial will increase almost immediately if it is exposed to a warmer surrounding.Food stuffs on the contrary are in bigger pieces. They have higher thermic stability. The temperature in the food will increase much slower. In view of these facts Ordinary household refrigerators and Themos Flask have inadequate cooling systems for vaccine.

Top Lid

When a normal refrigerator with front door is opened the cold air in the cabinet will fall out. When the door is closed new warm air has to be cooled. Normal food with good thermic stability will not be much affected. But the. increase of temperature in the cabinet may easily destroy the vaccine. A box with a top lid retains most of the cold air when it is opened. Therefore all Blow Kings Cold Chain equipment have top lid.A box with a top lid is preferable also because vaccine can be stored in the whole interior space.

Conclusion:

In view of the above facts Vaccines must always be kept, stored, and distributed at refrigeration temperature to preserve the effectiveness of the vaccines.

What is the importance of Cold Chain Equipment?

The Cold Chain guarantees Refrigeration Temperature

The system for keeping the vaccine continuously at the right temperature from the manufacturer, during storage and transport, and at the Health Centres is called the Cold Chain. Today, with the help of cold chain equipments from walk-in coolers to mobile equipment of small and large size vaccine carriers/cold boxes, immunization programmes has evolved having diversified in terms of operational strategy is reaching out to inaccessible areas covering 20% of the children population worldwide.

The system for keeping the vaccine continuously at the right temperature from the manufacturer, during storage and transport, and at the Health Centres is called the Cold Chain. Today, with the help of cold chain equipments from walk-in coolers to mobile equipment of small and large size vaccine carriers/cold boxes, immunization programmes has evolved having diversified in terms of operational strategy is reaching out to inaccessible areas covering 20% of the children population worldwide.

How do you choose right cold box/vaccine carrier?

Points to consider:

I) Vaccine storage capacity: How much vaccine will be carried? To calculate the quantity of vaccine that must be transported, see the information given on vaccine storage volumes as follows:

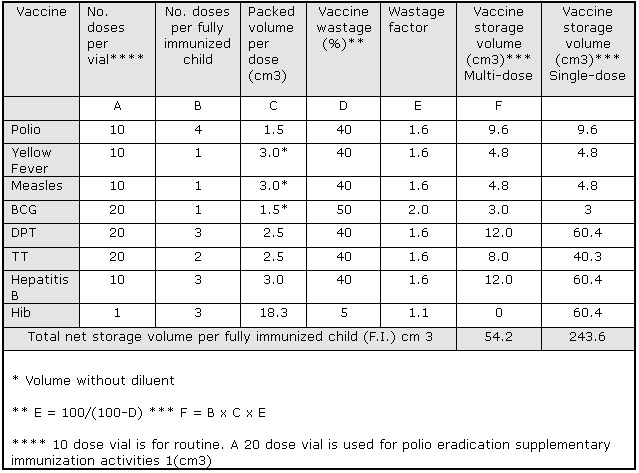

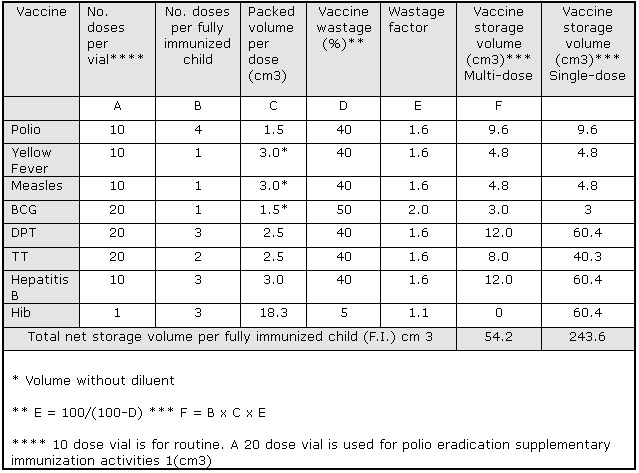

II) Vaccine storage volumes The following table provides data for estimating the packed volume of vaccine required per fully immunized child. Adjusting any of the figures which have been assumed in this table requires that the table be recalculated according to the prescription at the head of each column. Table 1: Packed volume per fully immunized child

I) Vaccine storage capacity: How much vaccine will be carried? To calculate the quantity of vaccine that must be transported, see the information given on vaccine storage volumes as follows:

II) Vaccine storage volumes The following table provides data for estimating the packed volume of vaccine required per fully immunized child. Adjusting any of the figures which have been assumed in this table requires that the table be recalculated according to the prescription at the head of each column. Table 1: Packed volume per fully immunized child

What is the right cold life required for your equipment?

The data for cold life "without openings" on the sheets in this section are an assessment of the longest time the vaccine can be stored in a cold box or vaccine carrier with the lid closed. Cold life has been measured at an ambient temperature of +43°C to allow for increased temperatures inside vehicles. It is recommended to double estimated requirements to allow openings of the cold box, plus delays in transportation. For example; if it is calculated that the proposed activity requires 24 hours cold life, double that calculation, and ensure the equipment has 48 hours cold life.

Weight: How will the Cold Box be carried? Weight fully loaded and durability can be graded according to how the box will be transported, Destination & How roughly it will be treated.

Durability: To what conditions will the cold box be exposed? The durability of vaccine carriers is partly represented by measure of "robustness" obtained during laboratory drop tests.

Weight: How will the Cold Box be carried? Weight fully loaded and durability can be graded according to how the box will be transported, Destination & How roughly it will be treated.

Durability: To what conditions will the cold box be exposed? The durability of vaccine carriers is partly represented by measure of "robustness" obtained during laboratory drop tests.

Is icepack included in the equipment?

At the time of placing an order it is important to check if icepacks are included with the box or not. If they are not included, select icepacks that will fit the chosen box. It is normally advisable to use same manufacturer's icepacks against which the equipment has been tested for optimal results.

Blowkings Standard products duly come with required no. of icepacks. However, it has been proven that for the sake of rotation and to cope with the loss it is useful to have an extra set of icepacks per cold box or vaccine carrier.

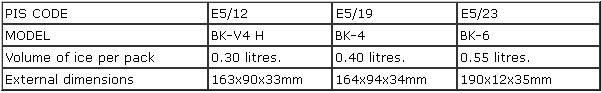

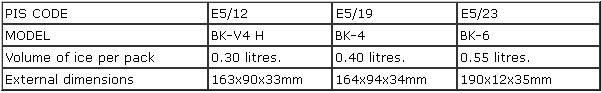

Blowkings manufactures three sizes of icepacks:

Blowkings Standard products duly come with required no. of icepacks. However, it has been proven that for the sake of rotation and to cope with the loss it is useful to have an extra set of icepacks per cold box or vaccine carrier.

Blowkings manufactures three sizes of icepacks:

What are the criteria for the classification of cold boxes and vaccine carriers?

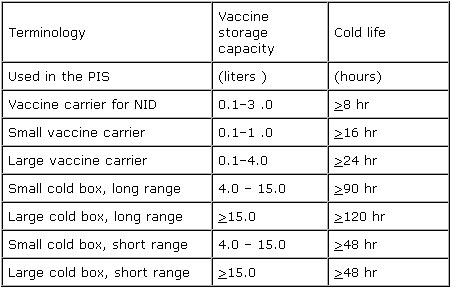

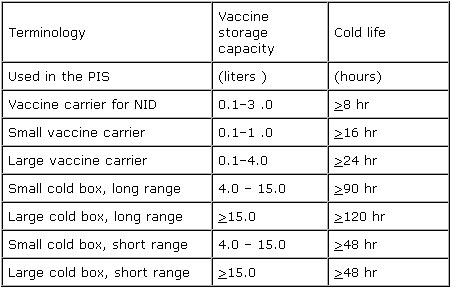

Table 2: Capacity of various types of vaccine carrier.

Specialized Cold Chain Products from Blowkings

Blow Kings has been part of cold chain program since 1985 & has step by step built up a complete programme of Special Products for the Cold Chain equipments to area specific needs since ordinary household refrigerators have inadequate cooling systems and capacity for vaccine.

BLOWKINGS PRODUCT RANGE

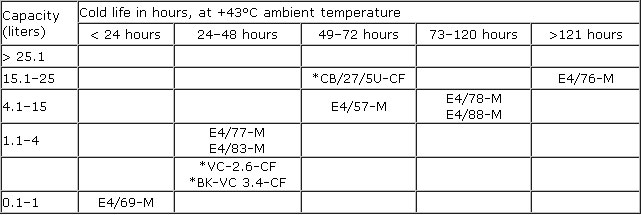

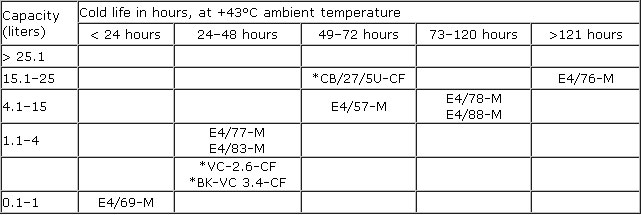

Table 3: Cold boxes and vaccine carriers grouped on basis of cold life and vaccine storage capacity.

BLOWKINGS PRODUCT RANGE

Table 3: Cold boxes and vaccine carriers grouped on basis of cold life and vaccine storage capacity.

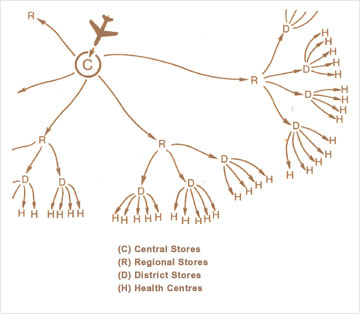

How are vaccines distributed?

Vaccines usually arrive by air in large cold boxes from the manufacturers. Central Stores near a central airport normally store the vaccine in small cold rooms or in large commercial refrigerators. From there they would be transported by various size cold boxes depending upon the cold life required & vaccine storage volumes to different centers.

Planning the Cold Chain Information and Assistance from W.H.O.

Information on the reason for the immunization programme, instructions which can help planning a Cold Chain, product information, and test results are available from the following address:

World Health Organization, E.P.I.

CH-1211 GENEVA, Switzerland